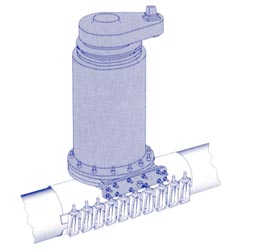

Inserta Valve

Ever since Power introduced the QuikValve™, installing a control valve into an operating line has been as simple as a lateral tap.

No loss of pressure. No costly shutdowns. Quick. Simple.

Now Power introduces the InsertaValve™, enabling Power Technology Services to drop valves into 10 and 12 inch mains with the same ease.

Installation time is less than 2 hours, typically much quicker than alternative methods of line stopping and cut-ins.

Line stop …simplified

If you’re looking for a simpler line stop, the InsertaValve™ delivers. The method is the same, the only difference is when you’re done, you take the valve with you to be used again.

- No Loss of Pressure

- Minimal Product Loss

- Completion time is less than 2 hours

- Much Faster Than Traditional Line Stopping And Cut-Ins

Material Specifications:

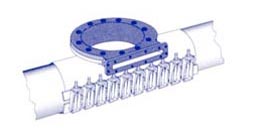

InsertaValve™Sleeve

Intended Use: Provides attachment to pipe for drilling and final assembly of the InsertaValve™ Control Valve. May be used on cast iron, ductile iron, steel, asbestos cement and C900 PVC pipe.

General: The fabricated sleeve will assure a 360 degree seal around the pipe under working pressures up to 150 psi. It will accommodate the equipment and fixtures necessary to drill the pipe and install the InsertaValve™ valve assembly without any interruption in service.

Materials: Made of ASTM A-36 steel, epoxy coated to 10-12 mils.

Flange: A special flange will mate with the InsertaValve™ installation equipment and valve assembly.

Neck: The precision manufacturing tolerances of the neck will assure proper alignment, and support, of the InsertaValve™valve assembly. The neck will incorporate a slide gate body that will provide a connecting flange and sealing surface for the slide gate housing. The slide gate body will also provide a sealing surface for the slide gate disk o-ring.

Bolts and Nuts: High strength low alloy steel bolts and nuts meeting AWWA standard C-111. Type 304 stainless steel bolts with Zylan coated nuts to prevent galling, are optional.

Lugs: Sleeve sidebar lugs will properly align the sleeve halves during installation, provide a bolting surface, and assure a 360 degree seal. The lugs will to prevent excessive stress on the pipe and assure a tight, durable, and resilient seal.

Mat Gaskets: Made of Styrene Butadiene Rubber (SBR) compounded for potable water service in accordance with ASTM D2000 3 BA715. The gaskets provide a positive 360 degree seal on the pipe and assure a tight, durable, and resilient seal. Other seals on request.

Coating: The sleeve will be lined and coated with fusion bonded epoxy. Epoxy to meet the requirements of AWWA C-213.

Armours: Heavy gauge type 304 stainless steel armour plates will bridge the gap between the sleeve halves.

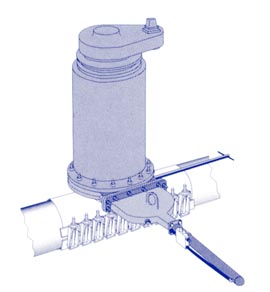

InsertaValve™Valve Assembly

General: Designed to be inserted into the InsertaValve™ Sleeve after the drilling procedure is performed, the Valve Assembly shall perform as a control device giving an effective shutoff of the flow. The valve will be installed in the open position, under pressure and under flow conditions without any interruption of service. The InsertaValve™shall give a full flow waterway after installation.

Plug: Constructed of urethane rubber, with a durometer of 65 Shore A. The plug shall seal on the on the inside diameter of the pipe and inside diameter to the drilled hole.

Valve Stem and Stem Nut: Manufactured of high strength bronze suitable for valve stems and nuts.

Gearbox: Made of SBR rubber, compounded for potable water service in accordance with the ASTM D-2000 3 BA715, with a durometer of 70 Shore A. The gasket shall act as the sealing interface between the valve flange and the sleeve flange. Other seals on request.

Bolts and Nuts: Grade 3 or better alloy steel, zinc plated for corrosion protection. Type 304 stainless steel bolts, nuts and washers are optional. Stainless steel nuts are Zylan coated to prevent galling.

The InsertaValve™requires a minimum depth of bury from the topside of the pipe of 40 inches. The physical height of the sleeve and valve assembly is 35 inches off the top of the pipe.

The InsertaValve™requires approximately 215 turns to completely open and close the valve.

Easy Installation

Install the InsertaValve™ sleeve on to the pipe

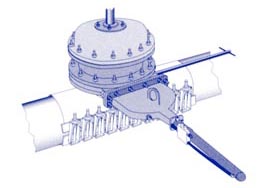

Mount the slide gate assembly & drilling machine. Drill pipe and close the slide gate.

Remove drilling machine & replace with valve canister.

Open slide gate. Remove slide gate assembly & seal rod.

Open slide gate. Remove slide gate assembly & seal rod.